| Japanese | |

|

|

|

| GH Craft is a leader in advanced composite technology for aerospace, nautical and land transportation industry. |

| GH Craft is organized as a group of specialized professional engineers who can shape and design the clientfs specification and product needs using their imagination, innovation and experience utilizing the cutting edge CAD/CAM tools and manufacturing facilities. We make full use of our composite material molding and processing expertise and designing capability of structural products. Our complete line of services includes production of aerodynamic structure and machinery; jig molding; parts production and assembling; structural tests; prototype production; and specific small projects. | |

|

Design Engineering: |

|

||||

|

|

|

||

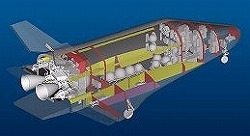

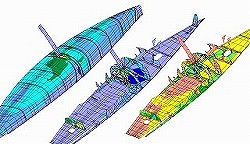

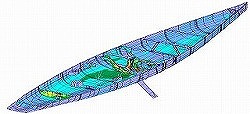

| Structure Designing, CAE, and Testing:

At GH Craft, we repeatedly analyze structural coordination between interior and exterior design and structural design at the concept design stage using CAE. Using CAD from various digital mock-up models for solid and surface, we analyze the structure in order to create the best fitted form. Composite materials make it possible to have such flexibility in designing, parts measuring, and form complexity; and this is where our abundant experiences in structural designing and manufacturing become valuable. Our development experiences in land, sea, and aerospace industries became our strength and it is crossing over these industries now. |

|

|

|

|

Tooling: |

|

|

|

| Large-size Molding Machines with self-heating integration | ||

|

|

|

| Composite Manufacturing Autoclave | |

|

|

|

Composite processing |

|

|

|

|

| Assembling Works | ||

|

GH Craft not only produces vehicle parts, but we are also capable of carrying out the entire production projects. The process starts with initial meeting with our clients understanding their needs. And then we select the best materials for the projects. Our analysis extensively uses CAE to create superior structural design. We often create our own tools for these projects, and use advanced composite materials for manufacturing and assembling. We can conduct total structure testing as well. We have experienced many new projects and learned designing and developing cycles. Our originality is based on such abundant experiences. We hope our customers will benefit from our services. |

|

|

|

|

||

| Copyright (c) 2005 GH Craft Ltd. All rights reserved.@ | ||